Shell structures are a captivating architectural marvel, admired for their elegant forms and impressive structural efficiency. Unlike traditional building methods that rely on massive supports, shell structures achieve strength through their shape, distributing loads across their entire surface. This allows for lightweight construction that can span vast distances, creating open, column-free spaces.

This comprehensive guide explores the fascinating world of shell structures, covering their principles, advantages, types, design considerations, and modern applications.

What are Shell Structures? The Essence of Form and Function

A shell structure is a thin, curved plate or slab of material, typically concrete or metal, that transfers loads through tension, compression, and shear stresses acting within the plane of the surface. Their defining characteristic is their curved geometry, which enables them to resist loads with minimal material compared to flat structures. Think of an eggshell – incredibly strong for its thickness due to its curved shape.

The Magic of Thinness and Curvature: How Shells Work

The strength of a shell lies in its ability to distribute loads efficiently across its entire surface. Instead of bending, as a flat slab would, the curved shape allows the loads to be transferred as tensile and compressive forces within the shell itself. This “membrane action” utilizes the material’s strength much more effectively, resulting in a lighter and stronger structure.

- Tension: Tensile forces pull the material apart. In a shell, these forces are often concentrated near the edges or boundaries.

- Compression: Compressive forces squeeze the material together. The majority of a shell structure experiences compressive forces.

- Shear: Shear forces act parallel to the surface, causing layers to slide past each other.

Key Advantages of Shell Structures: Benefits Beyond Aesthetics

Shell structures offer several compelling advantages over traditional building methods:

- Material Efficiency: They use significantly less material than conventional structures like beams and columns to span the same distance. This translates to cost savings and reduced environmental impact.

- Long Spans: Shells can span vast distances without intermediate supports, creating large, open, and column-free spaces. This is ideal for arenas, auditoriums, exhibition halls, and other large-scale venues.

- Aesthetic Appeal: Their graceful curves and organic shapes are visually striking and offer unique architectural possibilities. Shells can create dramatic and memorable spaces.

- Natural Lighting: The curved shape can be designed to optimize natural light penetration, reducing the need for artificial lighting and saving energy.

- Acoustic Properties: The curved surfaces can help to diffuse sound, improving the acoustics of large spaces.

- Structural Efficiency: The distribution of loads across the entire surface makes them inherently strong and stable.

Types of Shell Structures: A Diverse Architectural Vocabulary

Shell structures come in a variety of forms, each with its unique characteristics and structural behavior. Here are some common types:

- Spherical Domes: Domes are among the oldest and most recognizable shell structures. They are highly efficient at distributing loads evenly and can span large areas. Examples include the Pantheon in Rome and the geodesic domes popularized by Buckminster Fuller.

- Cylindrical Shells: These are curved in one direction, forming a barrel-like shape. They are typically supported along their longitudinal edges and can be used to cover long, narrow spaces.

- Conical Shells: These structures have a conical shape, with loads transferred towards the apex and base. They are often used for roofs or water towers.

- Hyperbolic Paraboloids (Hypars): Hypars are doubly curved surfaces generated by moving a straight line in space. They are relatively easy to construct using straight formwork and can be combined to create complex and visually interesting structures.

- Folded Plates: While not strictly shells, folded plates mimic shell behavior by creating a series of rigid planes that distribute loads efficiently. They are easier to construct than curved shells.

- Free-Form Shells: Modern computational tools and construction techniques allow for the creation of complex, free-form shells with unique and organic shapes.

Materials Used in Shell Structures: Adapting to the Form

The choice of material for a shell structure depends on factors such as span, load, aesthetic requirements, and cost. Common materials include:

- Reinforced Concrete: Reinforced concrete is the most common material for shell structures, particularly for large-scale projects. It provides excellent compressive strength and can be easily molded into complex shapes.

- Steel: Steel shells offer high strength-to-weight ratios and can be prefabricated for faster construction. They are often used for large-span structures.

- Timber: Timber shells can be constructed using laminated timber or plywood. They offer a sustainable and aesthetically pleasing option.

- Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for certain shell applications.

- Fiber-Reinforced Polymers (FRP): FRP composites are increasingly used in shell structures due to their high strength-to-weight ratio and resistance to corrosion.

Design Considerations for Shell Structures: Engineering the Elegance

Designing shell structures requires a deep understanding of structural mechanics and the behavior of thin-shell elements. Key design considerations include:

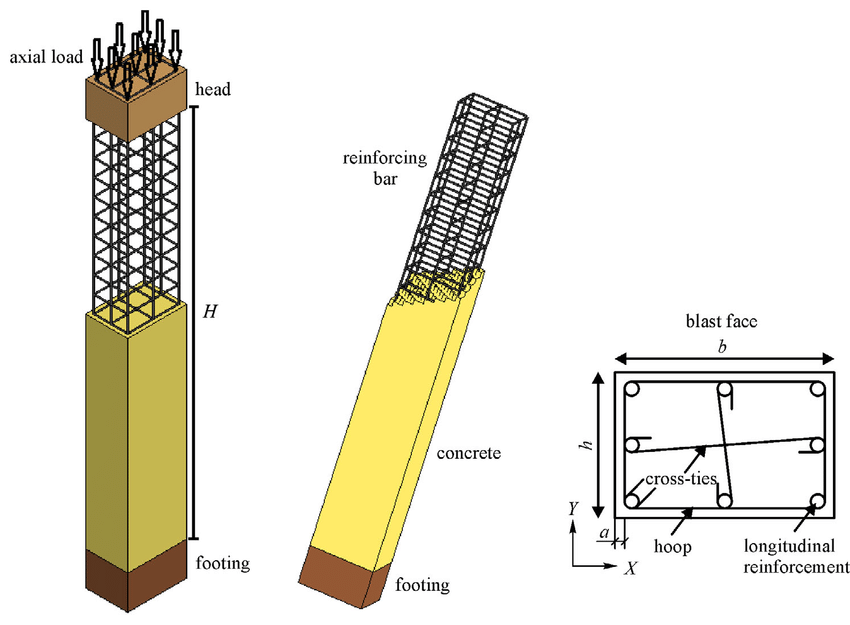

- Load Analysis: Accurately determining the loads acting on the shell is crucial for ensuring its stability. This includes dead loads, live loads, wind loads, seismic loads, and any other applicable loads.

- Shell Geometry: The shape of the shell significantly affects its structural behavior. The geometry should be optimized to distribute loads efficiently and minimize stresses.

- Boundary Conditions: The supports and connections at the edges of the shell must be carefully designed to resist the tensile and compressive forces.

- Buckling Stability: Shells are susceptible to buckling, which is a sudden and catastrophic failure due to compressive stresses. Buckling analysis is essential to ensure the stability of the shell.

- Reinforcement: Reinforcement is often required in concrete shells to resist tensile stresses and prevent cracking.

- Construction Methods: The construction method must be carefully considered during the design phase. The design should be compatible with the chosen construction technique.

- Material Properties: Accurate material properties are essential for performing structural analysis.

- Long-Term Behavior: Creep, shrinkage, and temperature effects can affect the long-term performance of shell structures. These effects must be considered in the design.

- Aesthetics: The aesthetic appearance of the shell is also an important consideration. The design should balance structural efficiency with visual appeal.

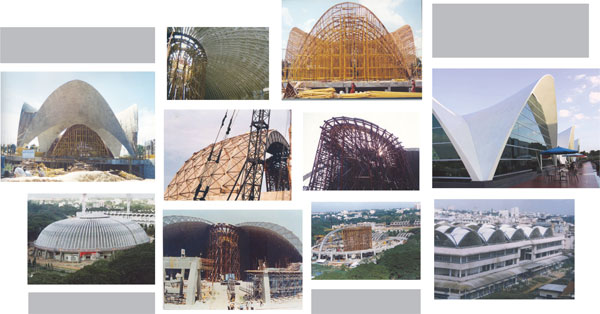

Construction Techniques: From Traditional Methods to Modern Innovations

Constructing shell structures requires specialized techniques and skilled labor. Common construction methods include:

- Cast-in-Place Concrete: This involves building a temporary formwork on site and pouring concrete into it. This method allows for the creation of complex shapes but can be time-consuming and labor-intensive.

- Precast Concrete: Precast shell elements are manufactured off-site and then transported to the construction site for assembly. This method offers better quality control and faster construction.

- Shotcrete: Shotcrete is a method of spraying concrete onto a formwork or directly onto a reinforced mesh. It is often used for constructing thin-shell structures with complex geometries.

- Fabric Formwork: This innovative technique involves using flexible fabric as formwork for concrete shells. This allows for the creation of complex and organic shapes with minimal material waste.

- Robotic Fabrication: Robots can be used to fabricate shell elements with high precision and efficiency. This method is particularly well-suited for creating complex, free-form shells.

Examples of Iconic Shell Structures: Architectural Masterpieces

Shell structures have inspired architects and engineers for centuries, resulting in some of the most iconic buildings in the world:

- The Pantheon (Rome): A remarkable example of a concrete dome built in ancient Rome.

- Sydney Opera House (Australia): A masterpiece of modern architecture featuring a series of soaring concrete shells.

- Gateway Arch (St. Louis, USA): A towering stainless steel arch that is a symbol of American expansion.

- Palazzetto dello Sport (Rome): A small sports arena designed by Pier Luigi Nervi featuring a ribbed concrete dome.

- Oceanogràfic (Valencia, Spain): A stunning aquarium complex designed by Félix Candela featuring a series of hyperbolic paraboloid shells.

Modern Applications of Shell Structures: Shaping the Future

Shell structures continue to be used in a variety of modern applications, including:

- Arenas and Stadiums: Providing large, column-free spaces for sporting events and concerts.

- Exhibition Halls: Creating open and flexible spaces for exhibitions and trade shows.

- Airport Terminals: Covering large areas with minimal supports, creating a welcoming and efficient environment for travelers.

- Churches and Temples: Creating inspiring and spiritual spaces with unique architectural forms.

- Water Tanks and Reservoirs: Providing efficient and durable storage solutions for water.

- Residential Buildings: Exploring innovative and sustainable housing solutions.

Challenges and Future Directions: Overcoming Limitations and Exploring New Possibilities

Despite their many advantages, shell structures also present some challenges:

- Complex Design: The design of shell structures requires specialized knowledge and software.

- Skilled Labor: Constructing shell structures requires skilled labor and specialized equipment.

- Buckling Sensitivity: Shells are susceptible to buckling, requiring careful analysis and design.

- Formwork Costs: Formwork can be expensive, particularly for complex shapes.

Future directions in shell structure research and development include:

- Advanced Materials: Exploring new materials with higher strength-to-weight ratios, such as FRP composites and high-performance concrete.

- Digital Design and Fabrication: Utilizing advanced computational tools and robotic fabrication techniques to create complex and optimized shell structures.

- Sustainable Construction: Developing more sustainable construction methods and materials for shell structures.

- Self-Healing Concrete: Incorporating self-healing concrete to improve the durability and lifespan of concrete shells.

Conclusion: Shell Structures – A Testament to Innovation and Elegance

Shell structures represent a remarkable achievement in engineering and architecture. Their efficient use of materials, ability to span vast distances, and aesthetic appeal make them a compelling solution for a wide range of building applications. As technology advances and new materials are developed, shell structures are poised to play an increasingly important role in shaping the built environment, offering innovative and sustainable solutions for the challenges of the 21st century.

Call to Action:

- Research Notable Shell Structures: Explore the work of renowned architects and engineers who have pioneered the use of shell structures.

- Learn Structural Analysis Software: Gain proficiency in structural analysis software used for designing shell structures.

- Connect with Experts: Network with structural engineers and architects specializing in shell design and construction.

By pursuing these actions, you can deepen your understanding of shell structures and contribute to the ongoing innovation in this exciting field.